Fabrication services: let’s bring your idea to life.

Fabrication is the engine of our company, it drives everything we do.

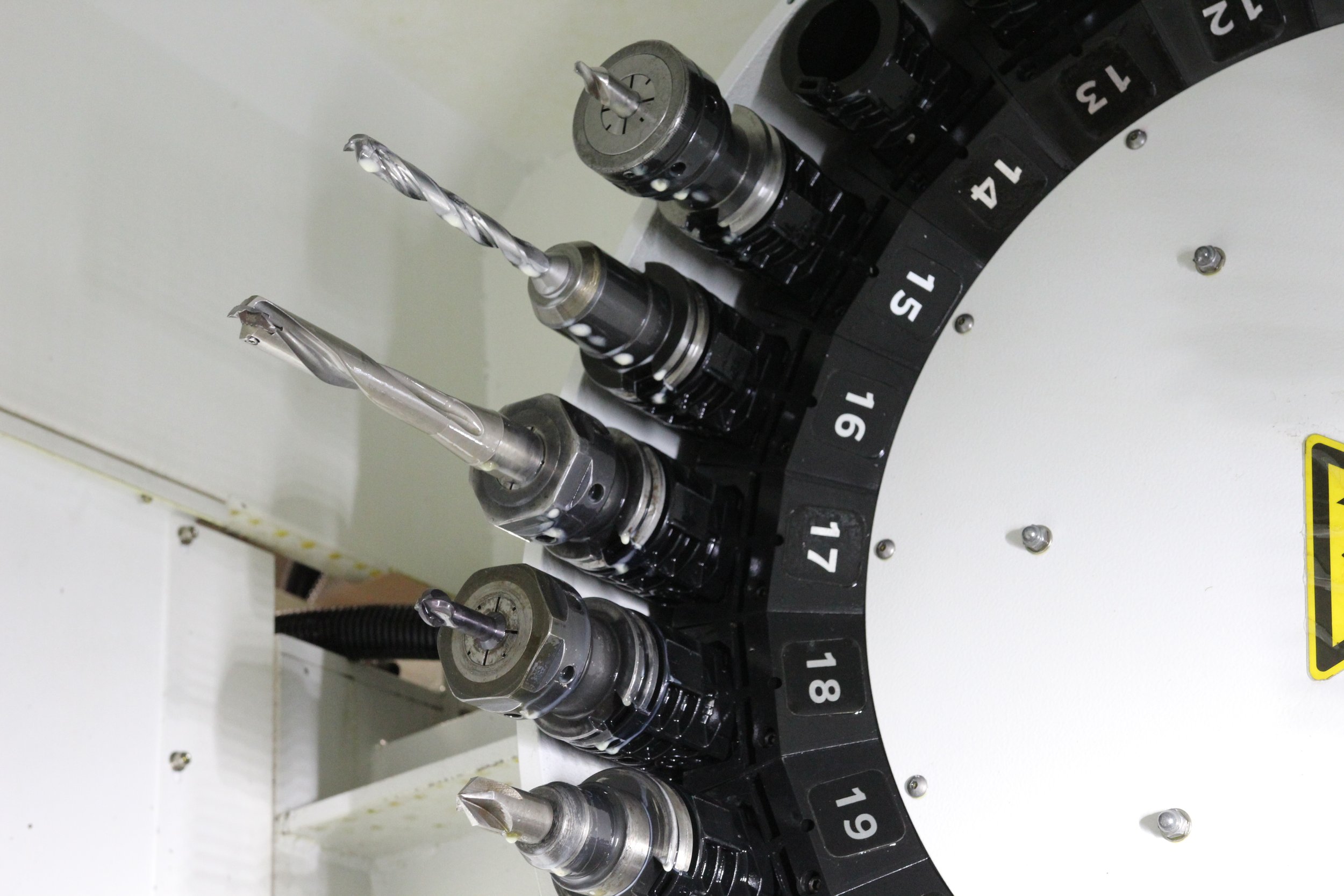

machining department:

Here at Ironmen Industries, we specialize in both CNC production and custom work.

Our equipment includes 5 CNC Lathes (two of which are live tooling), 3 Mills (2 milling centers, one manual mill 7.5 HP), two large engine lathes as well as many supporting equipment.

Our lead times are reasonable and dependable and given the urgency often negotiable.

We have state-of-the-art equipment for high-volume production with highly trained, skilled, and educated programmers/operators.

There is not a lot we can’t do in the machining world, and coupled with TIG/MIG welding, you might even expect complete assemblies at the most reasonable pricing.

We have Gibbs Cam Software for complex machining, and prototyping and can render your parts before running them to give a more accurate time management schedule.

We work closely with engineering.

We have 100% checks in place for high-volume work to ensure perfect quality.

We take the time to deburr your parts to save your employees from injuries.

As an added value, it’s about the experience. Our people and joyful environment in the machine shop make it a real pleasure doing business with us.

Forming Department:

With our 250-ton CNC press brake, we are capable of forming a variety of different types and sizes of materials on our 12’ bed. With our high-precision tooling, we can produce the parts that meet your quality standards and avoid die scratches and marks on your parts.

• Supporting our forming department is our 10’ shear and sheet/part G-Force crane assist.

• We also stock 5’x10’ mild steel, aluminum, and stainless steel. Ranging from 16ga – 1/4" thick, we can cut them to your desired size.

materials & saw cutting Department:

Here at Ironmen Industries, we offer many different sizes and styles of steel at a competitive price. Bulk orders are also available.

• We carry a variety of flat bar and angle Iron that starts from 1/2’’ wide and up.

• Our square and rectangular tubes come in sizes from as small as ½’’ up to 12’’ and bigger if the customer needs them.

• We also carry many sizes of round pipe, c-channel, and I-beam.

• If you’re looking for a round bar, we offer a variety of bars made from 1018, 1045, and 1045 chrome plated, and 4140 steel.

• If we do not have the steel in stock that you need, our sales team will gladly help you find what you’re looking for.

• We have 1 automatic and 2 semi-automatic bandsaws that are capable of cutting your steel accurately and quickly.

If you have any questions about our steel or cutting department, please don’t hesitate to give us a call.

welding department:

Here at Ironmen Industries, we strive to provide the best service around. We also have an In-house drafting team to meet high-quality engineered demands.

• Well experienced in custom and conventional structural steel buildings and miscellaneous metals

• Shop welding consists of approximately 15-20 Miller welders.

• Capable of most types of metal welding. (Mild steel, AR, cast, Aluminium, structural steel)

• CWB certified in GMAW and MCAW

• 2 - 5 ton overhead cranes and 3 - 2 ton

• Covering 36,000 sq. ft. of workspace

• 3 - Manual plasma cutters

• Specialty TIG welding in structural steel and Aluminium

• 2 - High tech Aluminium MIG welders.

on-site welding department:

We have approximately 20+ years of combined onsite labor experience. In custom stick welding and MIG. Let us bring our service to you, this is what we can offer:

• Our onsite service truck is equipped with a new Miller trailblazer 302 air Pak unit.

• Onsite Plasma cutting

• Onsite MIG equipment.

• CWB all position certified welders.

• Structural engineering work.

• Fall arrest training.

• Anything from farm repair to structural engineered jobs.

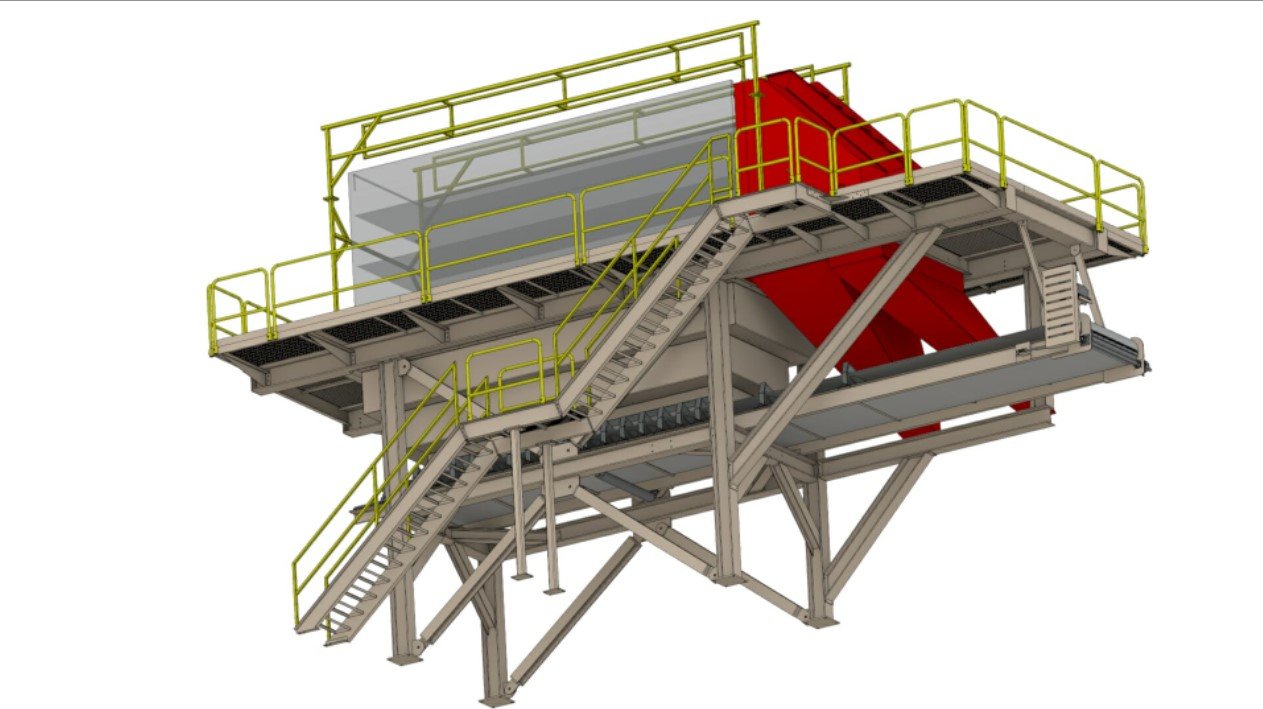

IN-HOUSE DRAFTING department:

Our drafting/engineering team is proficient in their field and strives to deliver anything ranging from engineered jobs to drafting projects.

• Capable of quick revisions to communicate with the customer.

• Product schematic creation, utilizing the SolidWorks software.

• Able to render proofs to send to customers for approval before production.

• Working closely with engineering, we are able to produce your vision quickly and efficiently.